Biological WWTPs – VFL-system (Vertical Flow Labyrinth)

Biological WWTPs – VFL-system (Vertical Flow Labyrinth)

- a patented system VFL for new and reconstructed biological WWTPs based on the activated sludge process is used (European patent EP 1919833)

- VFL-system is characterized by lower operating costs, because pumping is not made by motoric pumps but by mammoth pumps instead (30-50 % energy saving)

- VFL-system is characterized by the increased proportion of anoxic zones, which also leads to a better removal of macronutrients N and P (while saving energy for aeration)

- another advantage of the VFL system is a significantly lower production of excess sludge (predominantly stabilized), which brings additional savings in operating costs for sludge management

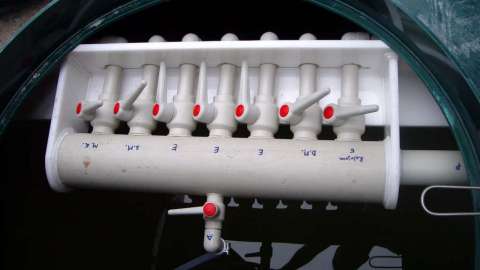

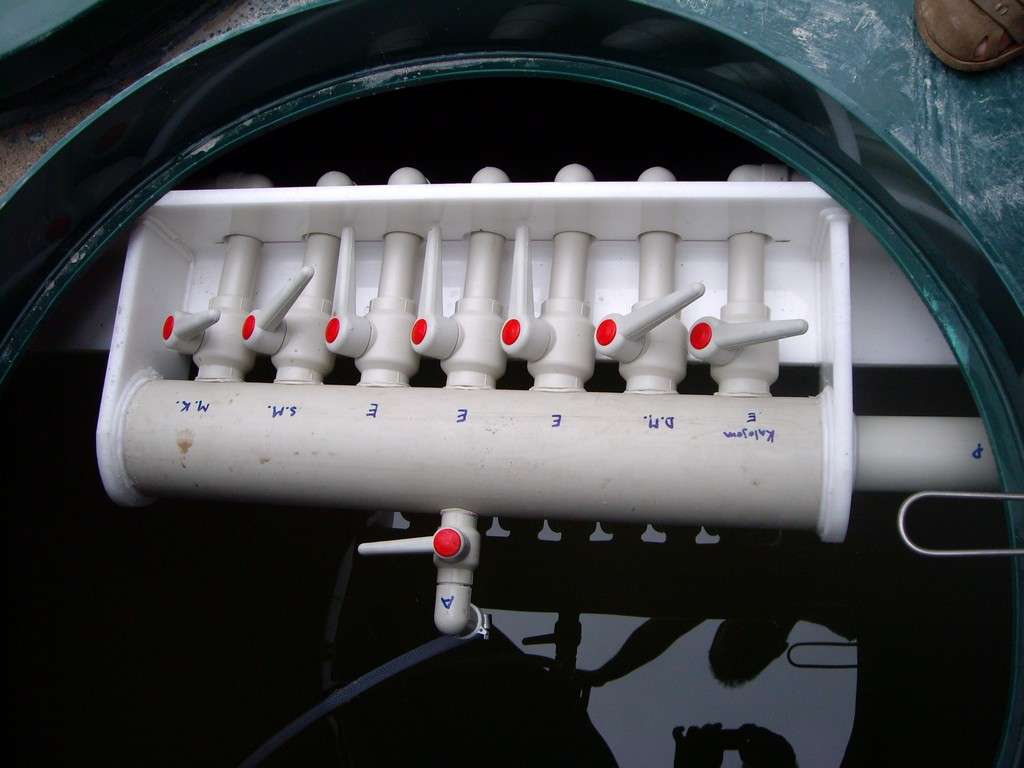

- smaller WWTPs are made of polypropylene (from home ones to hundreds of PEs), larger ones have concrete tanks with plastic constructions that form a system of oxic and anoxic zones with a vertical flow of water and a sludge-air mixture

- the project starts with hydro-technical calculations and elaboration of the project documentation, and it ends with handing over a complete WWTP, warranty service, and professional supervision