EVHflot – flotation plants (flotators)

EVHflot – flotation plants (flotators)

- fully automatic plant for continual purification of industrial sewage containing greases and oils of vegetable and animal origin, of petroleum based hydrocarbons oils, of fine fibers (paper, cellulose, textiles, plastics), of most heavy metals and other chemically well coagulable components of waste water pollution

- after the chemical coagulation, the formed precipitate is separated on the principle of pressure-expansion flotation – the DAF (Dissolved Air Flotation) process

- the system is suitable for waste waters from all branches of food industry, biotechnologies, biodiesel processing, from mineral oil processing and applications, and the like

- made of high-grade stainless steel with high-quality durable components

- supplied in a capacity line covering 10 different capacities from 1 m3/h to 90 m3/h

- a higher capacity is achieved by combining multiple several flotators with common service space, and with additional peripheral devices (chemical and sludge management)

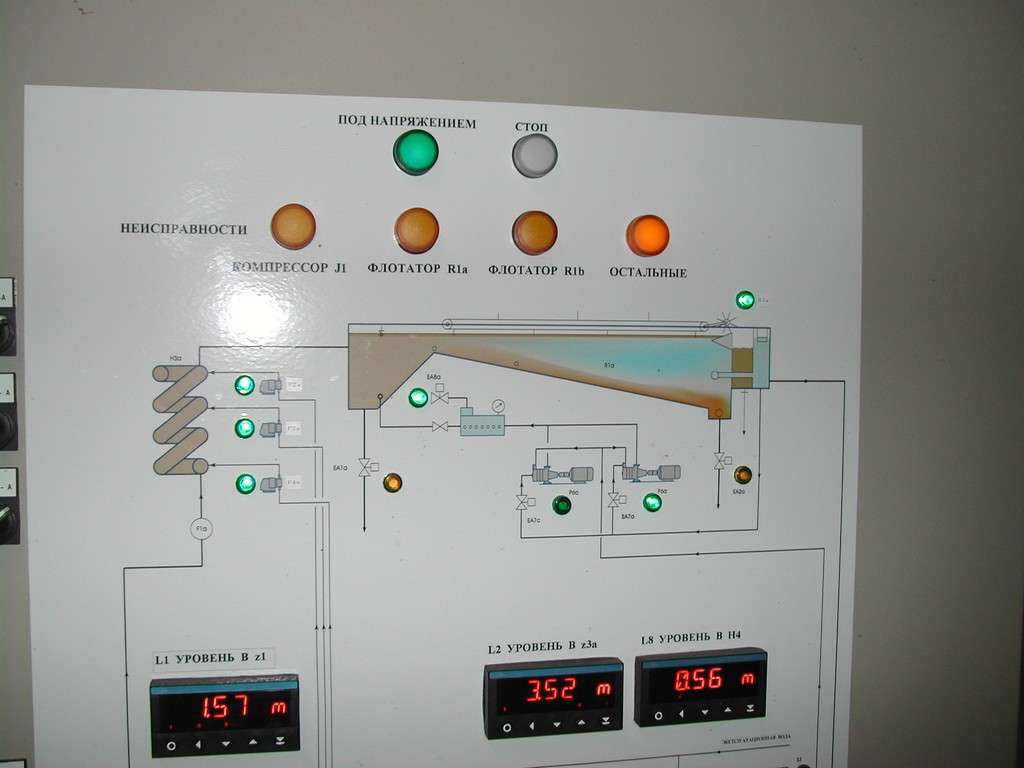

- the electrical distributor of its own, controlling the entire line operation (pumping, the accumulation tank level, chemical management, flow, pH, etc.) is part of the flotator delivery

- we work out a proposal for the necessary capacity of the flotation line with the complete technology, an authorized project documentation for all approval levels, a complete delivery and assembly, a guarantee test, operational documentation, a professional supervision and advice