sludge tank aeration

air distribution in detail

1st step of bioWWTP – aeration elements

1st step of bioWWTP – aeration elements

1st step of bioWWTP – air distribution

2nd step of bioWWTP – returnable sludge pumping

1st step of bioWWTP – sedimentation zones

2nd step of bioWWTP – contactor

2nd step of bioWWTP before installation

2nd step of bioWWTP

gang-board installation

sludge tank

waste water neutralization in a wine factory

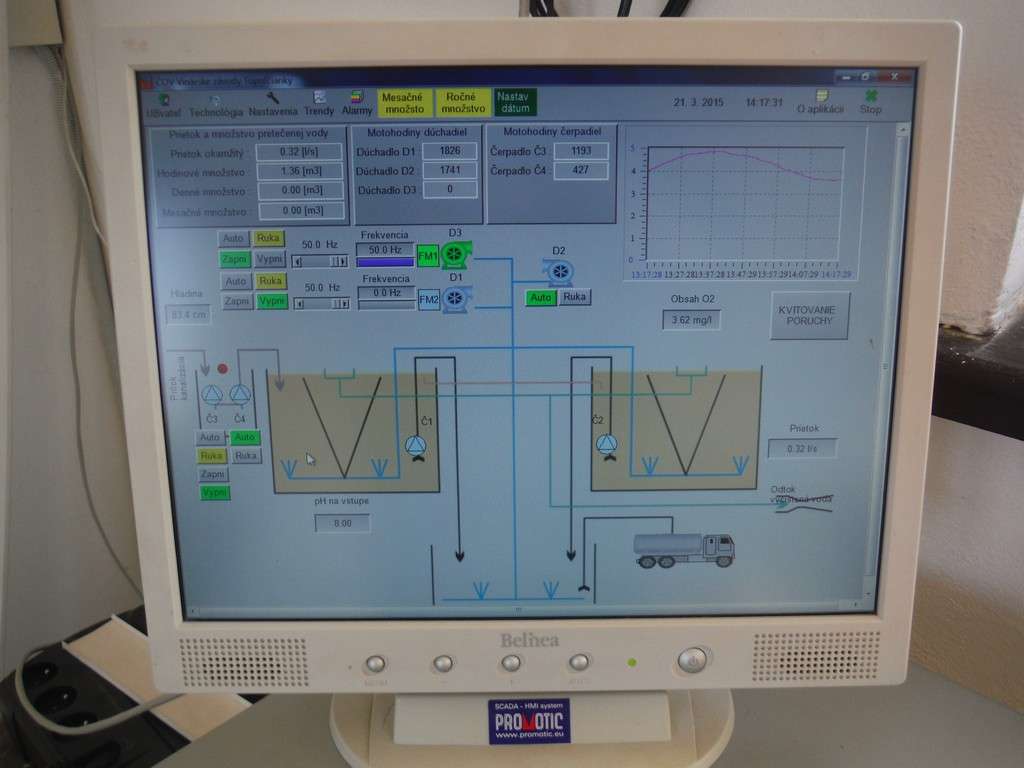

panel (visualization)

sludge water outlet from the sludge tank

new blower

sludge tank – input of air

2nd step of bioWWTP – a separation zone

sludge tank – tightness test

sludge tank – sludge poststabilization